Hello guys,

sorry to reply so late, I am pretty busy these days...

indeed I did some "architectural" experiments a few month ago, so here is what I found out in a nutshell

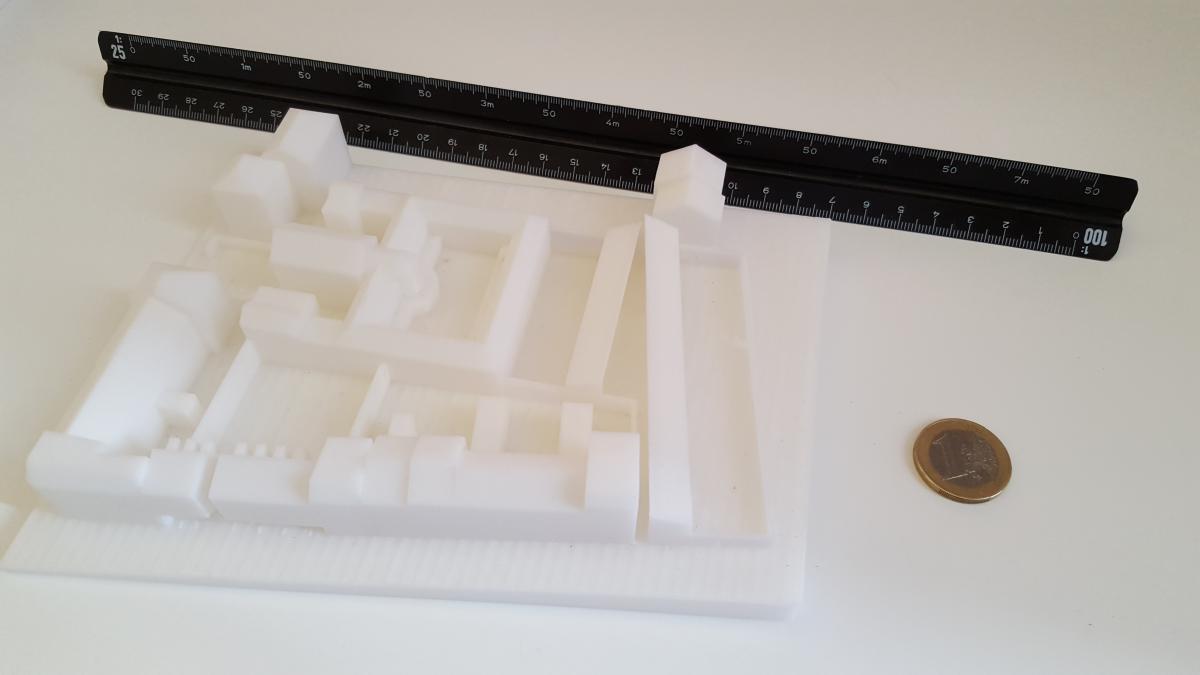

- Since I do 3D visualisation, the initial Idea was to use the created 3D models and use these for 3D printing. I learned that most times, depending on the project, the models need a lot of additional love and attention to prepare them for 3d printing. Generally you have to do a lot of boolean unioning to archive a limited number of printable solids, the fewer the better if you want to avoid additional glueing work.

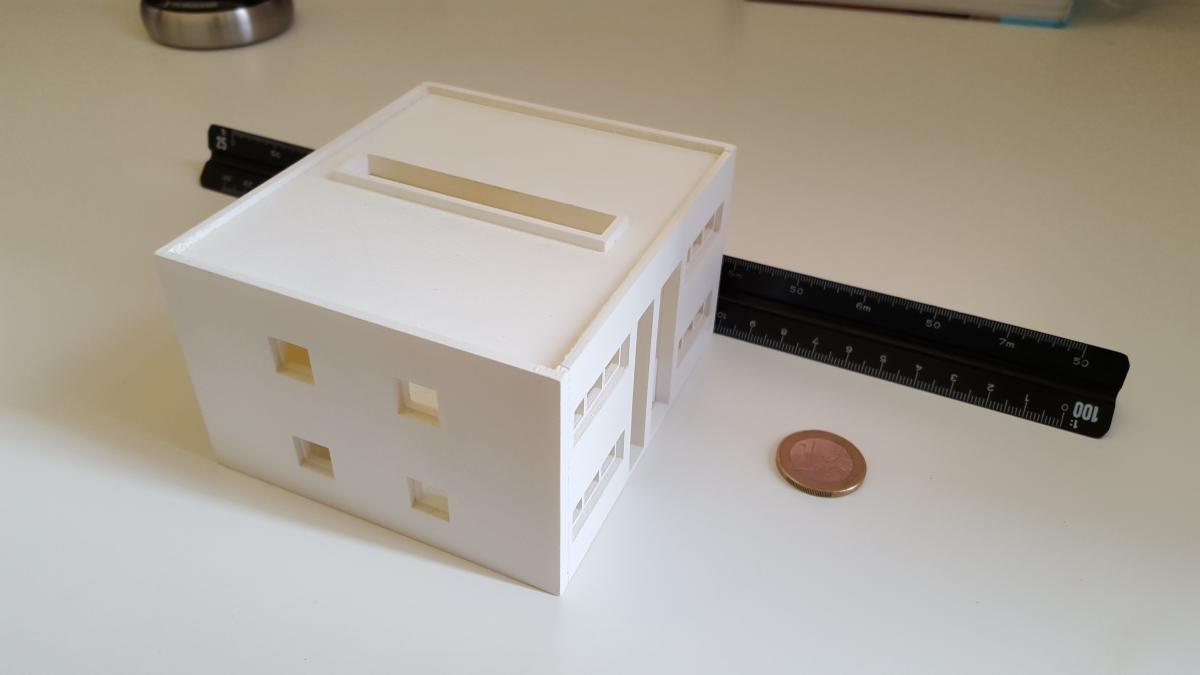

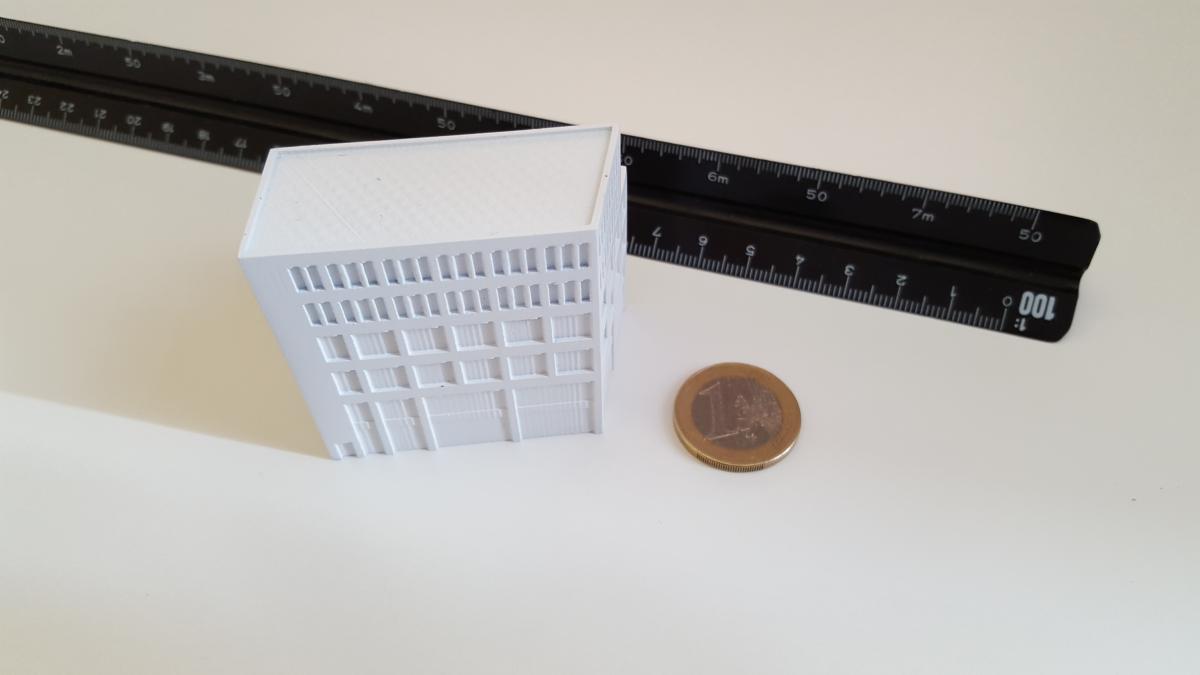

-Another point is that you have to rethink the whole model to work for 3D print. that means e.g. you have to examine delicate structures like railings, window frames and so on if they are printable at all, e.g. a 0,5 mm thick window frame will fail. Orientation of the model is also crucial since you get totally different surface qualities, vertical surfaces are usually the best, horizontal top surfaces have noticeable print pattern on them, bottom surfaces can look even worse.

Depending on the project and the targeted quality this means that you might need to post process the print by using putty and / or sanding the print.

-Warping can be a problem too, especially on larger structures with large windows and the same time closed walls, or horizontal boards with small height, especially if you plan to print the objects in several pieces.Overall, I had the best experiences with Ultrat but have not tried hips so much, since the support removal was pretty bad during my first tries (that was shortly after they released hips, so this might be better by now due to the new drivers...) Note that also with Hips, warping was an issue!

-The prints are transluzent, that means that for most projekt it is advisable to airbrush them to achieve a better readability of the surface.

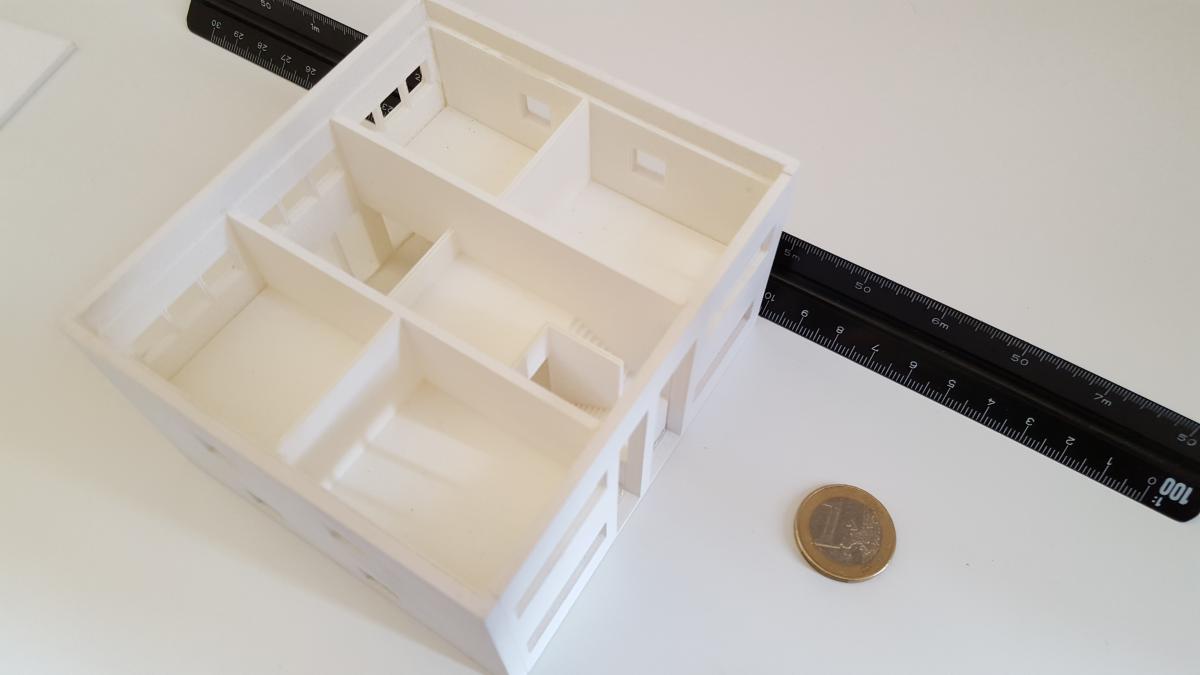

-From a business perspective (and this is very important!) you have to differentiate between simple solids resembling the scales M 1:1000 or M 1:500 and complex prints with Interiors like M 1:100. The first are very unproblematic, they are easily modeled print well and can be post processed very easy. The latter is way more complicated because really everything can go wrong. Removal of the automatic generated support can be a big pain when dealing with small structures, so you might want to use custom build supports (more work).

Complex structures with small caves or cavities can be very hard to reach for postprocessing, this might force you to split up the model more and then re glue it (more work). Warping can cause your parts to cause problems when putting them together.

That's it for now, I might add some points later.

best

Andreas