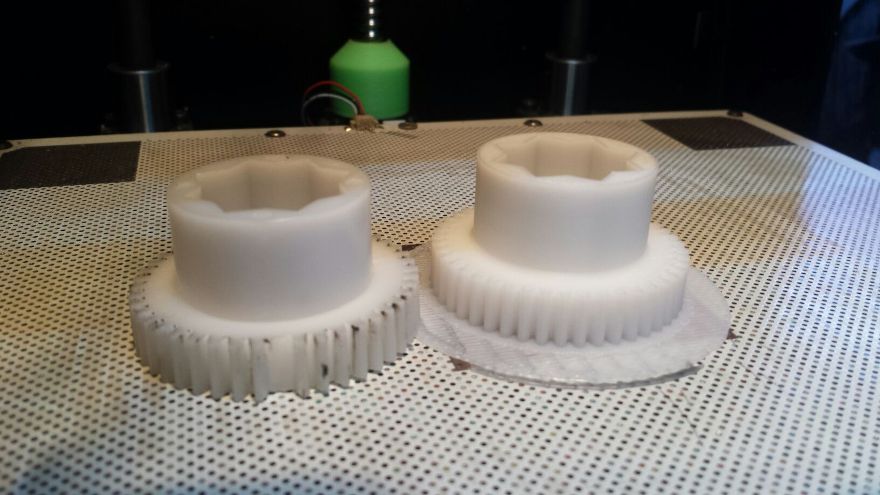

Printed in Z-HIPS at .190 Wonder how much force it can take? Time will tell.

Keep us posted :)

Will do.. I'm printing a back-up gear in Ultrat just in case he grenades this one.. He sent me a video of it working empty. Youtube is taking forever to process it..https://www.youtube.com/watch?v=uoc_fKnNwRk

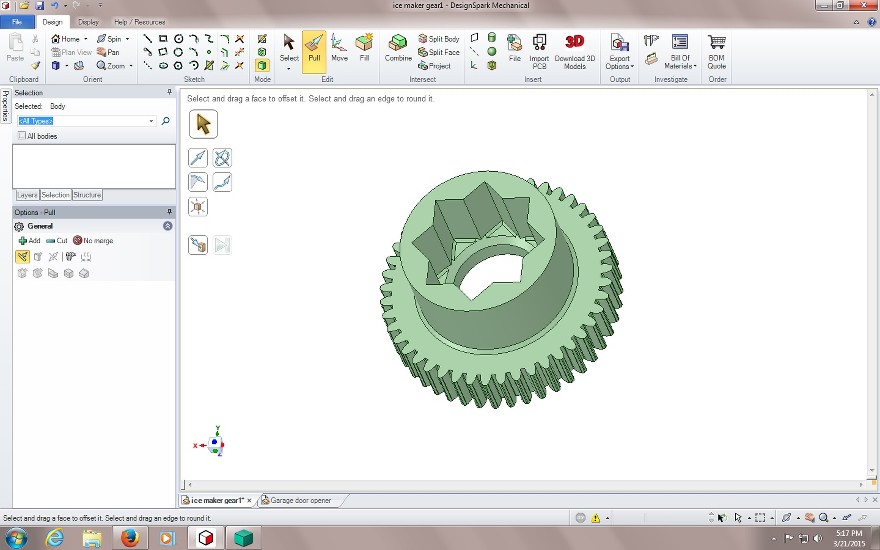

The teeth on yours look better than the original. How'd you design them?

A lot of luck!! lol.. Measured outside and inside diameter of teeth. Then measured width at base of tooth. Assuming it was a 20 degree pressure angle put a 20 degree bevel on both sides and rounded until it looked right.. Gears are not really my thing..

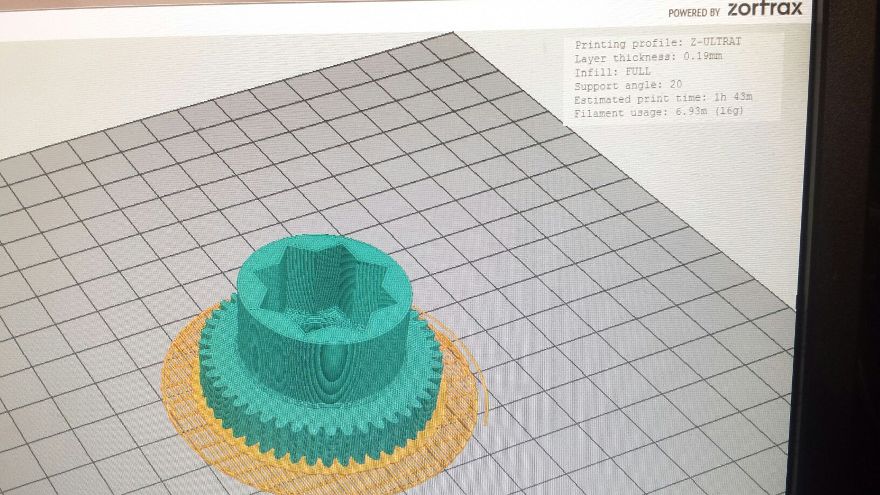

In case anyone was wondering the accuracy of filament usage on Z-suite, figured I'd test it.. Gear in Z-ULTRAT..

Actual cost of part..$1.00 in materials..

That’s awesome!!!

Kyle - Gearotic can generate gear tooth profiles that can probably be imported into DS and it is fairly inexpensive: I've not used it myself yet, but it has a pretty good reputation.

Mike

Cool, Mike, thanks for that link!

Another link: http://www.3ddoctors.net/templates/gears/spurgear.html#

Another link: http://www.3ddoctors.net/templates/gears/spurgear.html#

Holy cow that's an awesome site! :lol:

Looks familiar...

https://www.youtube.com/watch?v=d5QRqzc-yks

EDIT: Lol, whoops. Just saw that this was already posted.

Looks familiar...

https://www.youtube.com/watch?v=d5QRqzc-yks

EDIT: Lol, whoops. Just saw that this was already posted.

Now it's not just a little link though.. :D

Now it's not just a little link though.. :D

Yay, I'm helpful! :lol:

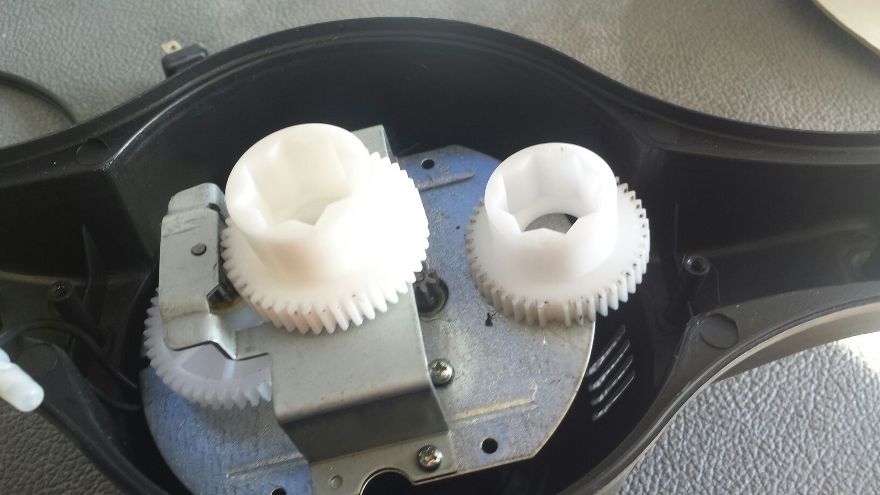

That would be the hand of Helcatt078.. LOL

Update!!! Neither the Hips nor Utrat gear held up under serious load. :( Part of the problem is the infill on the teeth. Be really cool if we could select number of walls.. Any way.. Now I'm printing a mold to resin cast the gear.. Might be a one shot mold but we'll see. Going to use Smooth-cast 385 and maybe even try the ONYX..

PolyMax or one of the Taulman materials, like the new "Alloy 910" might do it.

PolyMax or one of the Taulman materials, like the new "Alloy 910" might do it.

Might try this too.. Never heard of them before. Here in the US though.. http://www.innovative-polymers.com/images/specs/Classic-Shore-D/IE-3075.pdf