I bought 2 of these nearly 2 years ago specifically to print Nylon. They both take for ever to warm up and then often get hot end failures I have tried everything the support staff have suggested from full bed pre heating and changed anything that has elctricity going through it.

So I spent half of Sunday trying to get to the bottom of why, sometimes I get a good clean print, a lot of the time I get birds nests and prints I cant separte from the raft.

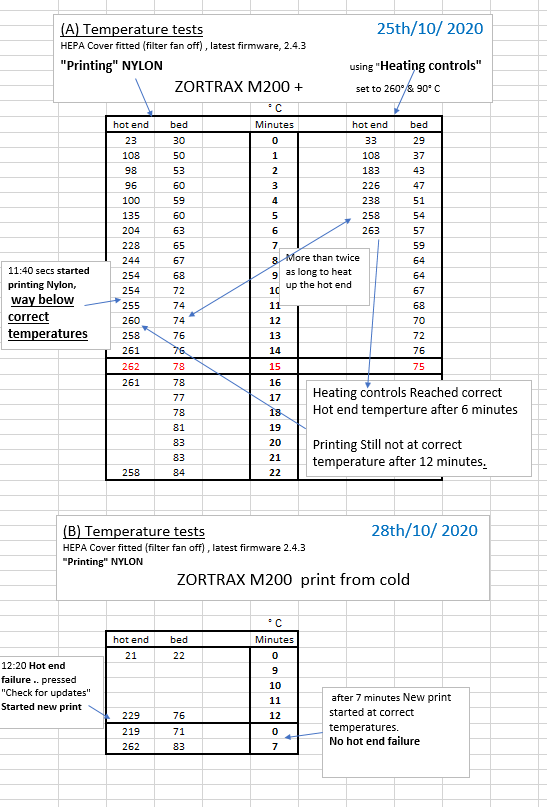

See attached as there are fundamental firmware problems that new hardware is not going to fix

-

Sometimes it gives up trying to warm up and gives (what I now know is a spurious) “Hot end failure” Proof: see attached … using Heating Controls it warms up the hot end in 6 minutes.

I have spent a lot of money on the advice of “Support” trying to fix these hot end errors which are caused by bad firmware not hardware. -

Sometimes it starts printing at way below the specified temperature so i get birds nests and prints I cant remove from the bed or raft.

Conclusion: Zortrax know the hot bed is way under specified at 150W and have tried to manage the warm up, through the firmware, to make it appear that both the hot end and the bed are warming up at the same speed.

This is why if you observe the temperatures they go up and down like a yoyo.

Will the new v2 hardware include a 200w? hot bed or upped the voltage … if so it will prove they have given us the run around on this problem and cost me a lot of time and money as i have two of them.