Got contracted by the suppliers to make some custom tap handles for a bar.

Great Job, how many castings you have to do?

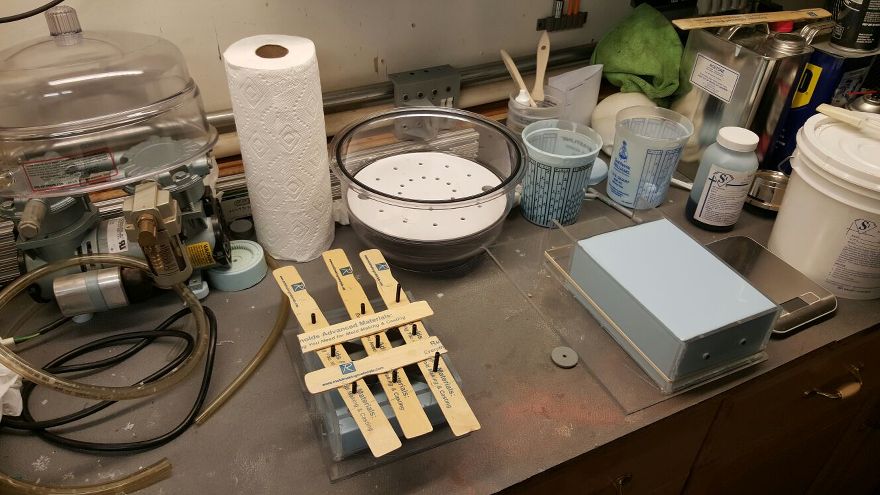

I need 3 Beam and 2 Svedka handles, and a topper for each. That is the mold with all the paint sticks on it. Creating registry keys with steel balls held on with magnets. I'll take pics of that one in the morning.

Very interesting! Did you apply acetone vapor to the parts or any coating?

Andreas

Real pro looking, Ive been casting some prototypes as of late. I was having parting line issues, so i ended up 3d printing a Jig to help overcome the issues i was having and incorporated the registry keys into it. I did cheat though, I outsourced my master pattern and had a stereolithography print done with bead blast, cost me close to $300.00.

Very interesting! Did you apply acetone vapor to the parts or any coating?

Andreas

I dipped them in acetone very quickly and let them dry over night. Sanded smooth using 200 grit followed by 600 then 1500. Dipped once more and let dry.

Real pro looking, Ive been casting some prototypes as of late. I was having parting line issues, so i ended up 3d printing a Jig to help overcome the issues i was having and incorporated the registry keys into it. I did cheat though, I outsourced my master pattern and had a stereolithography print done with bead blast, cost me close to $300.00.

Thanks! What kind of parting line issues were you having? Also... If you are looking for an AWESOME release agent for silicone to silicone.. I use the 200 spray.. Best stuff I have found to date!!!!! http://www.smooth-on.com/Release-Agents-and/c9_1123_1226/index.html

Parting line wasn't clean enough, so the final product came out amateur looking, its a 3 part mold too which was time consuming, the new jig I've designed should cut the prep time by at least 75%, hate working with clay. Thanks for the recommendation! Hopefully i can share some of my prints, and projects here in the near future.

GREAT JOB SO FAR.

what is the material you are pouring into the molds?

GREAT JOB SO FAR.

what is the material you are pouring into the molds?

Smooth Cast 327. It's the same as the 325 with a longer pot life and cure time.

Thanks for posting your experience. I have a project coming up in the new year that requires molds for PU parts. Any tips, tricks or other insights with your mold making would be gratefully received. I followed your link for mold release. Thanks for that.

Geeze - those look a little like the business end of an RPG - be careful about putting them in carry-on luggage :D

Nice work!