Our M300 Dual prints smaller parts well with no issues, but when prints cover most of the bed the following happens:

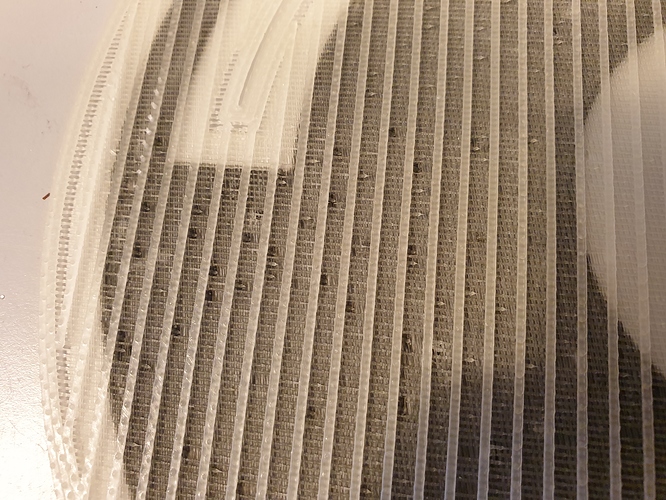

- When laying down the stringy parts of the raft where the extruder travels the longest - the extruded string breaks here and there leaving a strand sticking up into the air.

When the top layers of the print is added the loose strand creates a bump.

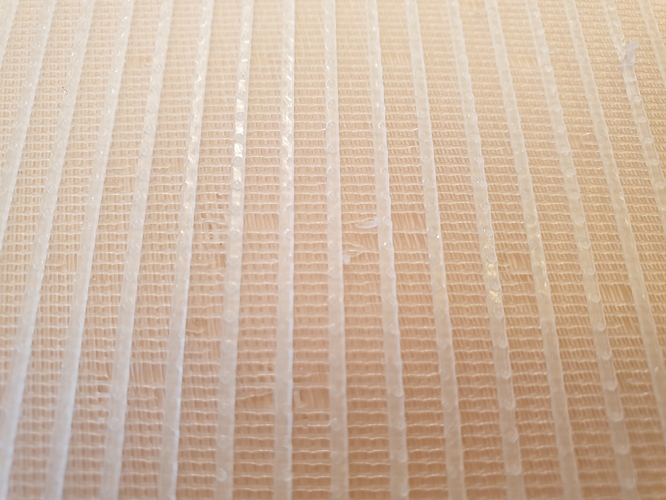

-

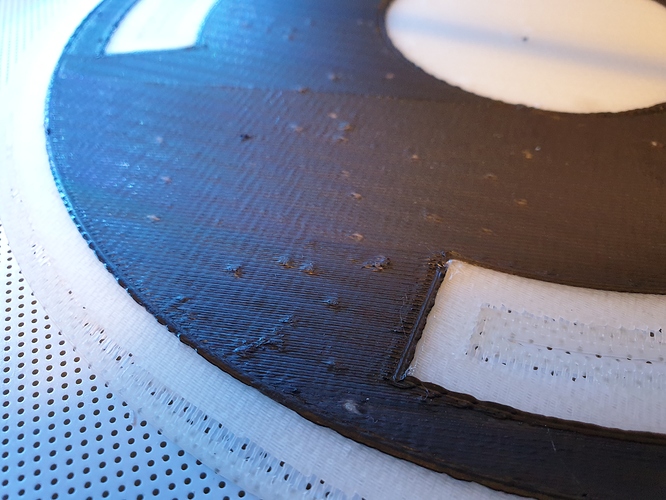

When extruding the main build material, the bumps cause a defect in the print.

-

The main build material will then give a Jam error on the first or second layers. possibly because the bumps obstruct the nozzle.

I can add that I have performed maintenance on the extruder, and there is no material build-up there. - And as mentioned above this does not seem to be problem for smaller prints.