Back in July I had lots of problems with a Z-PETG model that printed OK the first couple of times, then failed horribly after that. I posted here about it.

Eventually I replaced the nozzle, went back to printing Z-ABS and Z-ULTRAT and everything has been fine since.

Yesterday I tried to print another of the same Z-PETG model and immediately had similar problems recur.

On the first print the nozzle was far too close to the bed - while printing the first layer of the raft almost no material at all was being deposited (the nozzle didn't scrape, at least).

I cancelled that (unplugged the M200 - I don't think there's a way to cancel during the raft), did an autocalibrate, and tried again.

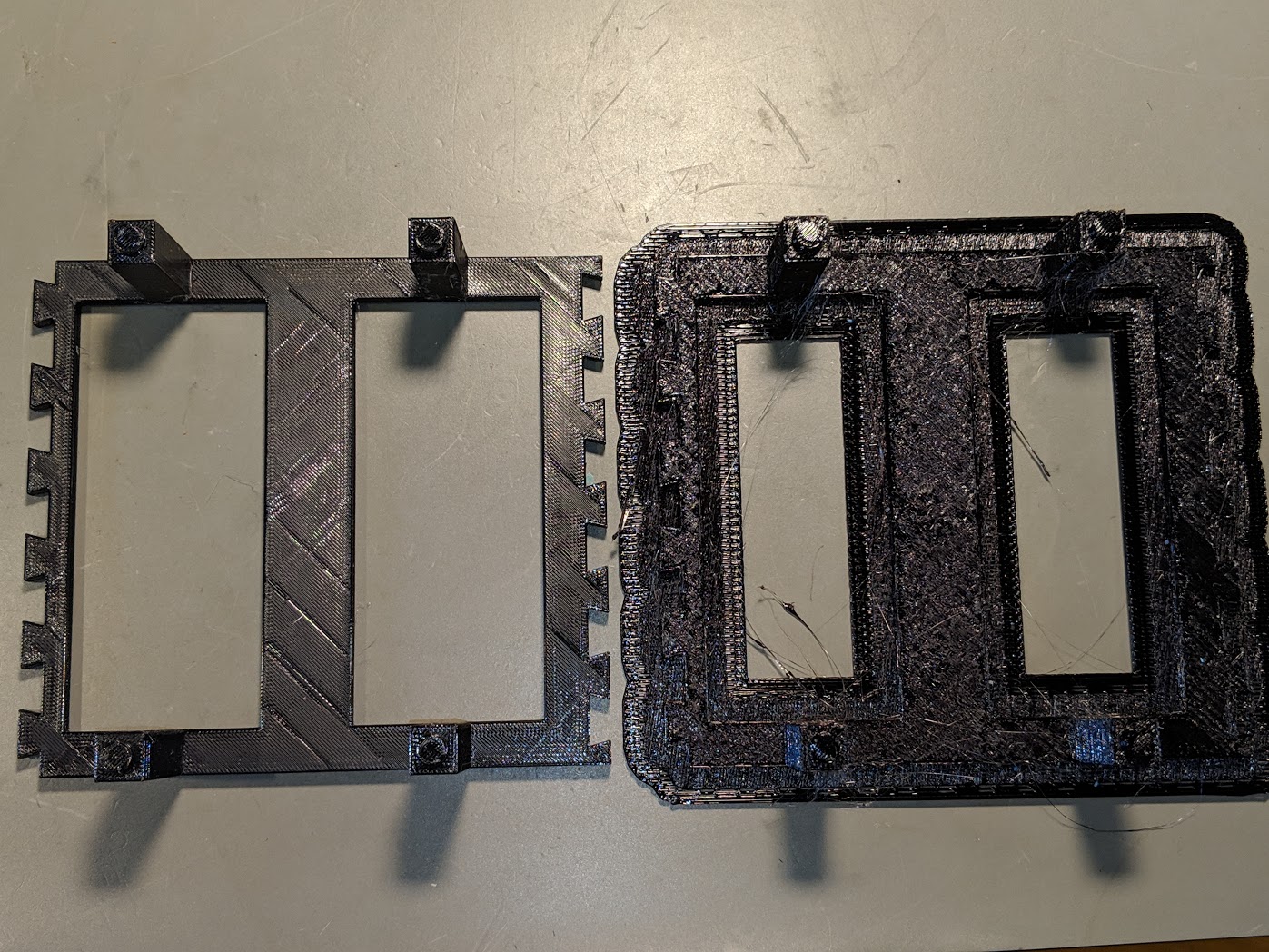

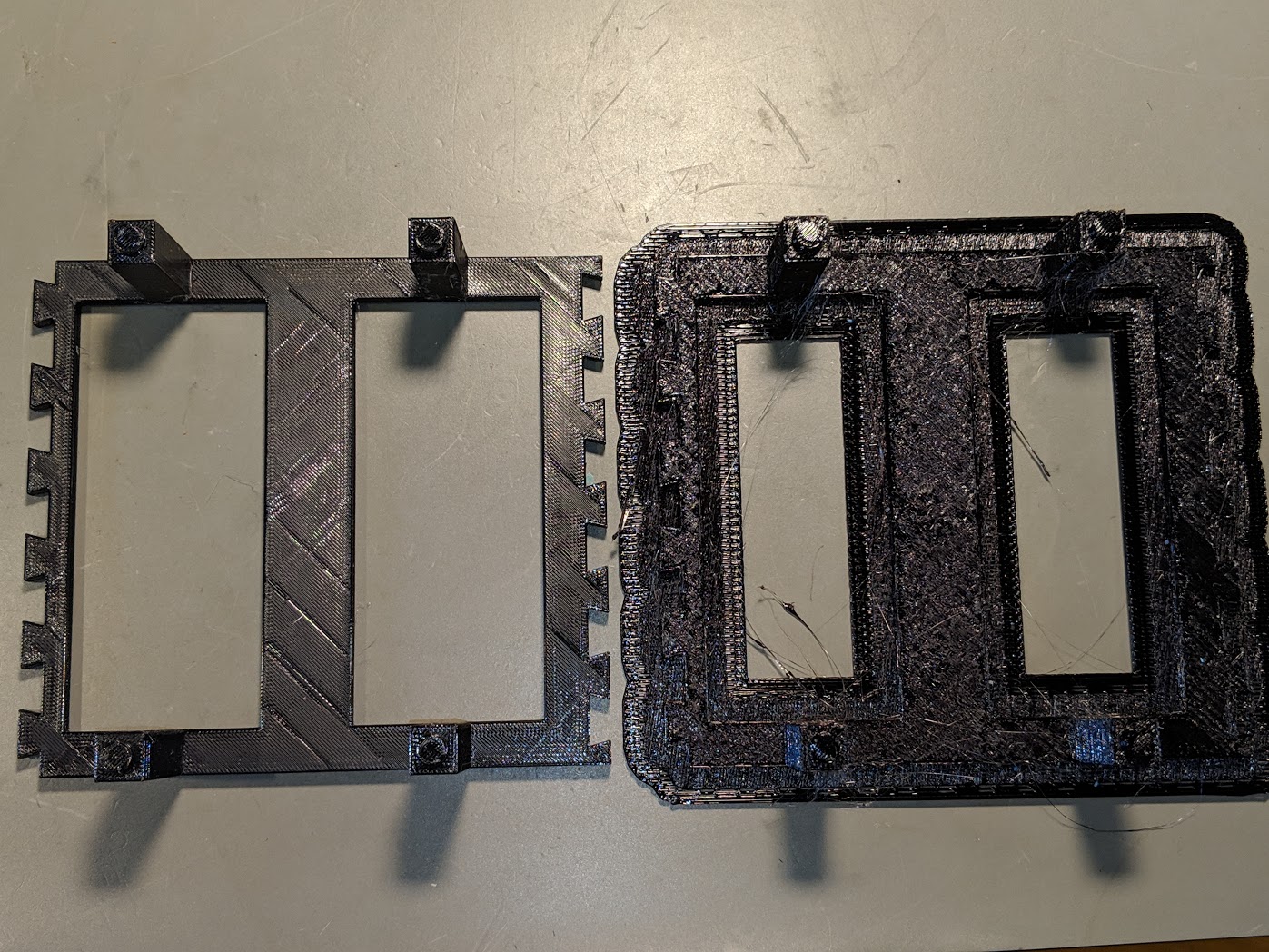

This time the nozzle deposited a normal amount of material. I left it running overnight, but got the result on the right, in the photo.

The part on the left is the same model, printed in July before the problems got bad (it's got some imperfections, but not serious ones).

I'm stumped. Any advice?

(M200 firmware 1.3.0, Z-Suite 2.7.2.0 on Windows, .zcode produced yesterday on that Z-Suite version from July's .stl.)

.zcode: https://nerdfever.com/images/zortrax/xylene_dl5.zcode

.stl: https://nerdfever.com/images/zortrax/xylene_dl5.stl

Check the z-axis coupler, make sure setscrews are tight..Inspect squares for damage. I'd probably also lightly scotch brite table contact squares and nozzle tip in case something on them making bad contact, partially unscrew and tighten nozzle (while hot).

Check to see you can run the .35mm wire thru new nozzle and when you do a filament load cycle, it drops essentially straight and diameter no smaller than .4 from new nozzle (I dont know what it should be for petg, for abs/hips/ultrat I get .45 to .55 on nozzles that don't need to be cleaned/replaced. Anything less than nozzle dia, 0.4, gotta be bad i'd think).

Thanks; will look at it, but immediately after printing the bad part above, I re-loaded Z-ABS and was able to print a perfect part on the first try. (Same nozzle, of course.)

It's very strange.

I'm also going to try printing Z-PETG while telling the printer that it's actually got Z-ABS, just to see what happens.

Thanks; will look at it, but immediately after printing the bad part above, I re-loaded Z-ABS and was able to print a perfect part on the first try. (Same nozzle, of course.)

It's very strange.

I'm also going to try printing Z-PETG while telling the printer that it's actually got Z-ABS, just to see what happens.

Dave,

Z-PETG is a very dense, therefore demanding material and it needs special treatment.

https://support.zortrax.com/printing-tips-m200/

It looks like the nozzle/hotend is getting clogged. Do you have some spares?

I'm printing your model at the moment.

I wouldn't print Z-PETG on Z-ABS profile because of too high extrusion temperature of Z-ABS.

You're welcome to contact me via PM, if you have more questions.

Dave,

Z-PETG is a very dense, therefore demanding material and it needs special treatment.

https://support.zortrax.com/printing-tips-m200/

It looks like the nozzle/hotend is getting clogged. Do you have some spares?

I'm printing your model at the moment.

I wouldn't print Z-PETG on Z-ABS profile because of too high extrusion temperature of Z-ABS..

FWIW, I seem to have found a workaround for this.

The problem seems to be that the PETG wasn't flowing smoothly - the extrusion gear would stumble a lot and eventually the nozzle clogged.

I set the M200 on "External Materials", "PETG", and then changed the extrusion temp from the default of 235 C. (Note, I'm using genuine Zortrax PETG, with the standard genuine Zortrax 0.4 mm nozzle.)

255 C was better, but not enough.

270 C is MUCH better; almost perfect. Maybe even a little higher would be perfect (I'll try 275 C next).

(How did the model print for you, Marcin?)

============

Edit: Thinking about this some more, this model printed fine the first 2 or 3 times I tried it, then started failing. While all along the printer prints Z-ABS and Z-ULTRAT 100% perfectly.

I'm wondering if the thermistor (or whatever is used to measure the head temp) has gone non-linear. Perhaps it's measuring temp correctly at ABS/ULTRAT temps, but wrong at PETG temps, and my changing the extrusion temp is just compensating for that? (Just guessing here - trying to theorize what might be causing this.)

Hi Dave,

I think I've the same problem, Z-PETG Grey spool, printed with Zortrax Material.

Tomorrow I'll try to print with your parameter.

Thanks.

Emanuele

Dave, Emanuele,

I'm getting mixed results. I'm checking different extrusion temperatures.

Do you guys have quite new hotneds or they've worked over 300 hrs already?

Dave, Emanuele,

I'm getting mixed results. I'm checking different extrusion temperatures.

Do you guys have quite new hotneds or they've worked over 300 hrs already?

Hi Marcin,

I have't yet had the opportunity to try to print with Dave's parameters,but I think I try them as soon as possible.

My hotend is still the one arrived with the printer, I tried to clean the nozzle with acetone, I do not know how many hours of printing it has.

Hi,

i’ve printed a skull with Dave parameters.no problem during printing, but I think the quality it’s not too good.

Seems a very small object, and probably stays too hot during printing. Try 2 of them at the same time, with a few centimeter distance.

regards

Andi

Hi Marcin,

I have't yet had the opportunity to try to print with Dave's parameters,but I think I try them as soon as possible.

My hotend is still the one arrived with the printer, I tried to clean the nozzle with acetone, I do not know how many hours of printing it has.

You can check it in Menu -> Information -> Printer information

Z-PETG and Z-GLASS do not solve in acetone, so cleaning will not be effective. After a completed printing process with Z-PETG, it's good to print a small object with a less dense material, Z-ABS for instance. Just to get rid of the Z-PETG residues inside the hotend. Or simply replace the nozzle/hotend with a new one.

https://support.zortrax.com/printing-tips-m200/

Hi all,

my printer has about 275 hours of printing, I know that acetone does not solve the PETG, but actually my last prints were with Z-ABS, so I tried to clean it before starting with Z-PETG.

I have read the support pages, I try, when possible, to print something in ABS after using Z-GLASS.

@goldenage a print with two small models with Zortrax parameters.

Thanks for reply!

Do you have a high moisture environment? What I have learnt from Nylon is that every filament takes moisture over time, I had an old spool of Z-ULTRAT that was unuseable because of moisture. After drying it performed flawless again.

regards

Andi

Do you have a high moisture environment? What I have learnt from Nylon is that every filament takes moisture over time, I had an old spool of Z-ULTRAT that was unuseable because of moisture. After drying it performed flawless again.

regards

Andi

Hi Andi,

I do not think so, the spool is new, I opened it just before using it and gave me this problem, but I’ll try to dry it.

Thank you