Hi Norman,

I am glad to see that you are still trying to solve this issue and agree that this issue is a kind of recall type trouble … I have not imagined that I do spend large amount of time for trouble shooting on this machine, I just bought this for my business without annoying this kind of issues and just wanted to concentrate on my business … hahaha

I have to OPEN THIS THREAD AGAIN !!!

After my last post, I did had a trouble of this issue again. That was for 13 hours printing with Z-ABS. Printing stopped just in 4 hours. So I reported this to Zortrax soon. They have assumed that this trouble is complicated than it seems to be and the possibility of Android board is losing the information and restarting itself. And they recommend me to send back my machine to the reseller here for diagnosis…

I just looked back the situation how my trouble was happening from the beginning, giufini’s case that the issue happens just after powering on the machine, and your case. Then I came to the point “High Temperature material”

In the beginning, I had been having this issue with Z-ABS, then run out Z-ABS spending 2 rolls for garbage. Then I switched using Z-HIPS. Reconnecting the bottom fan wiring, making the room underneath the machine for cooling purpose with 4 corner blocks, then situation had been getting better and had succeeded for longer printing with Z-HIPS at last. Now I have had this issue again with Z-ABS.

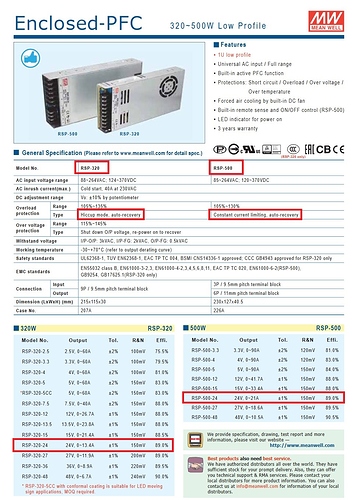

Z-ABS needs more temperature (275 degree in C) than Z-HIPS (250). This means that machine needs more power draw and increase the chance of over heating. I also find your latest post about PSU over heating and totally agreed for it !!

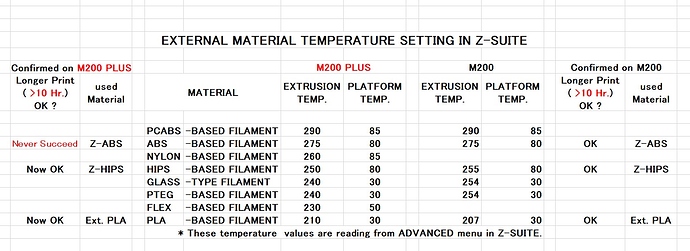

I just summarize this in the table bellow.

As you see in this table, the materials I used so far is Z-ABS, Z-HIPS, and external PLA. So if I try to print PCABS, same trouble will happen, I guess.

I am not sure which material giufini was using, but if he set the higher temperature material, this trouble will happen in earlier stage … I think.

Then tried to 13 hours long print again with Z-HIPS Yesterday and succeeded.

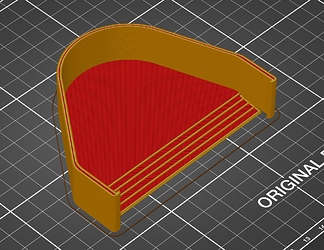

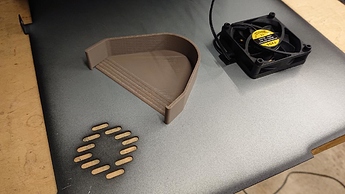

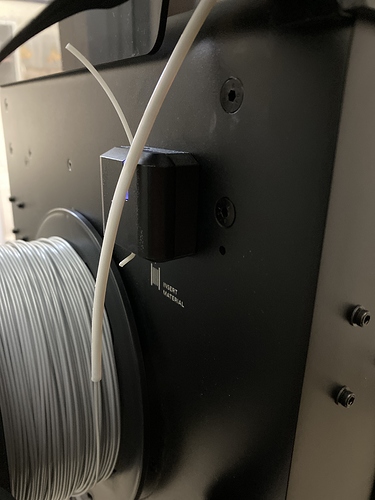

Now I follow your idea and made inlet cover like you did!

M200-InletCover-03.stl (7.0 MB)

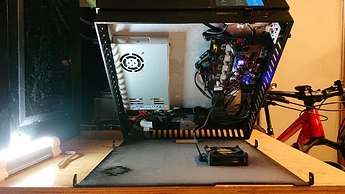

Now I am trying 13 hours long print with Z-ABS. This time the inlet cover for PSU fan as in the picture is attached. Currently 11 hours past, two hours to go !!

I will report again :