Hello Karolina,

I will fill the support form soon, but there is other users who has the same problem.

Therefore the argent you mentioned should be here soon, explain, and give us the solution.

Basically what we can do is showing you some hints and tips which may lead to the solution.

Our time is limited which can be spent on this issue, So I want you do some test and find solution inside your company, Zortrax, then give us a guide, please !

It is hard, at least for me, to do all the possible tries which you suggest like how about this or that …

If it is done in soon, that may be ok, but if it takes long hours and need more materials, it is just a waste of time and money for us … This M200 PLUS costs roughly $3000. If I count my time spending on this issue so far, it can be easily far more than this price. Wise user may throw this machine away, get other reliable machine and continue his/her business, because it is cost effective. The reason why I am still sticking to this problem is just the curiosity and desire to solve something as an engineer, maybe …

I bought Zortrax for business use, not the hobby use to play around…

Now I ask you how about trying the 2days long printing with bottom fan wiring disconnected in your place?

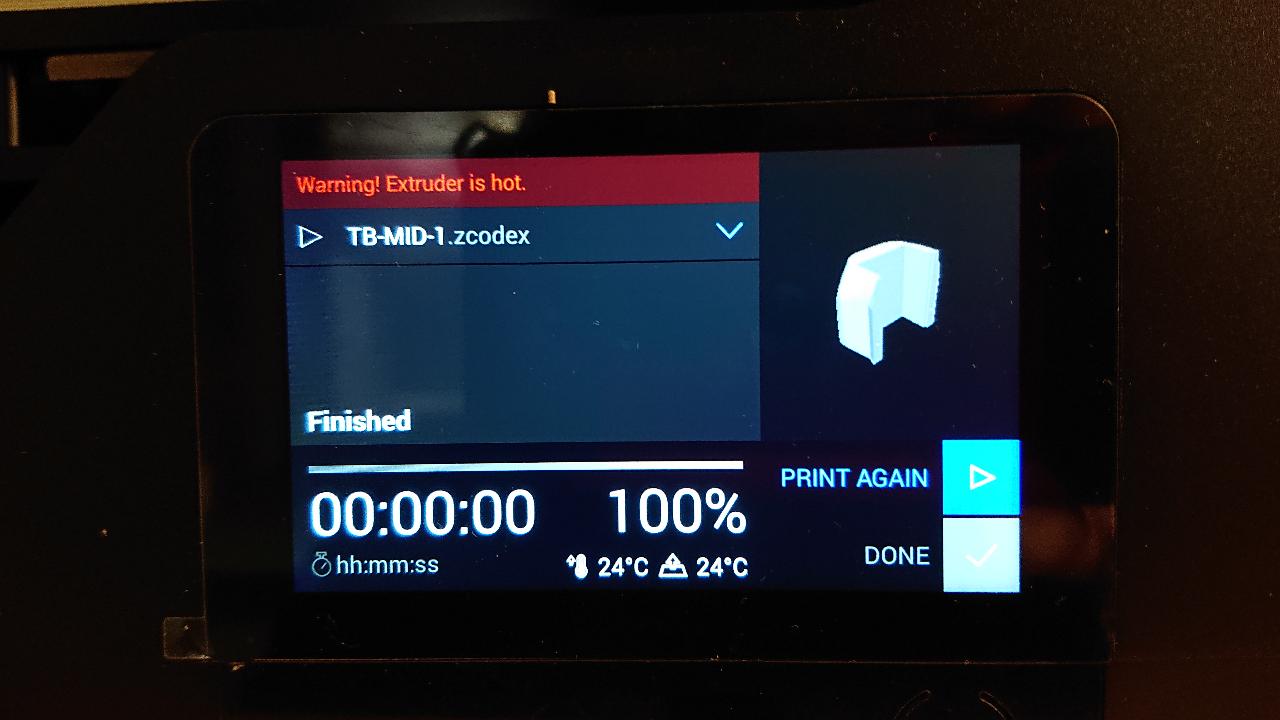

Hint is the position of extruder when print is stopped. Normally it goes back to the home position, but it stays just the position where print is stopped but LCD screen says Finished 100%.

Maybe you can cover the slits on 3 sides of side metal panels, two right /left side and one backside, with some duck tape to increase the chance of this trouble happen faster !?

I want to try above, but currently too busy to work on my project…

I am looking forward to hear the result !!!

Hello giufini,

Thanks for the post!

At this point, I am still suspicious about thermal runaway.

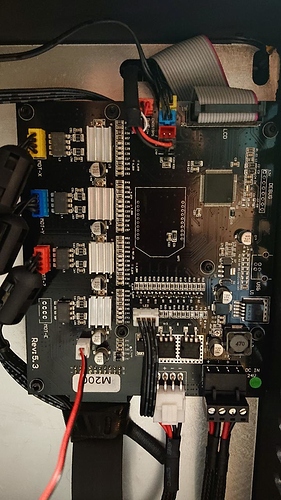

Because the printing time was extended when I put back the disconnected bottom fan wiring. When print proceeds, the heat bed, big heat source!!, is getting close to the mother board underneath.

And now I saw your video and have had a bit confident.

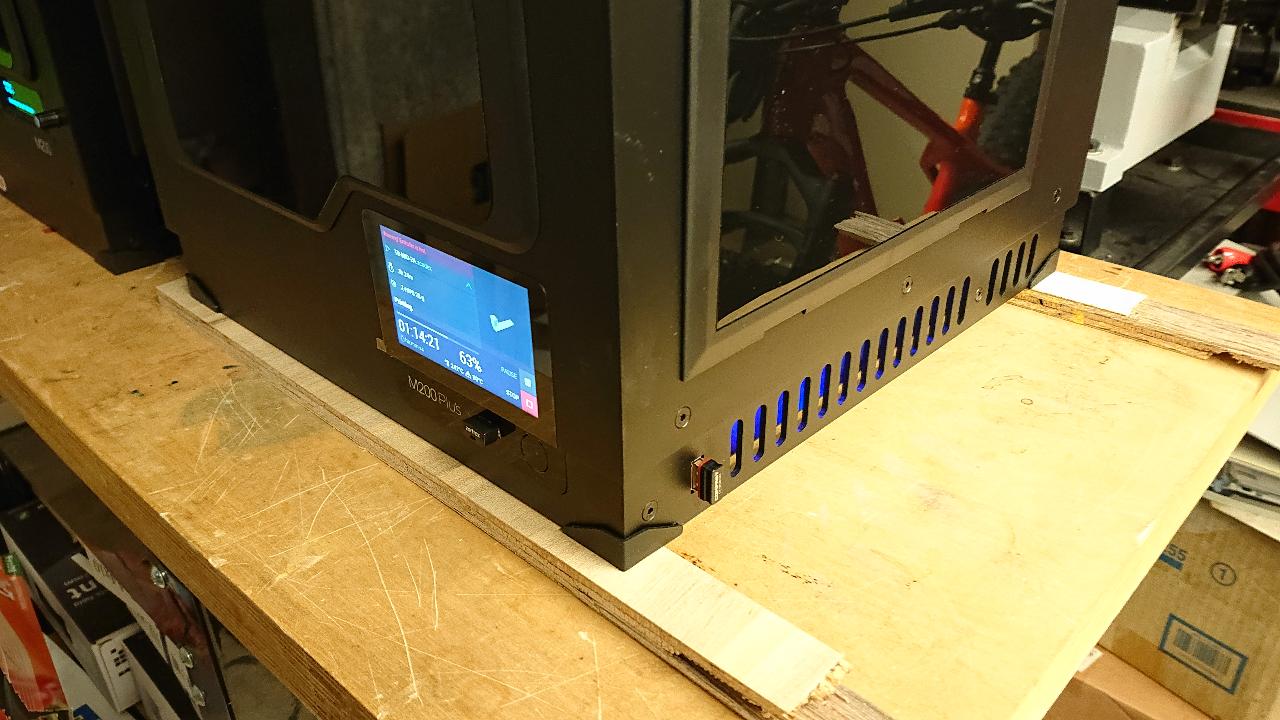

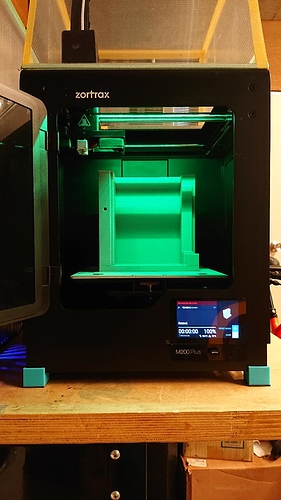

There is some box right side your M200 Plus, which has label “APC” in front. That may be blocking the fresh air coming into M200 Plus, I think. How about checking the bottom fan working ok and put nothing on right side.

Currently I put wooden plate underneath the machine and raise it up just 10mm above the desk.

When you open up the bottom plate, you will see the clearance between the fan and the desk where machine is put on is very little, say roughly 5mm! From that little clearance this fan is sucking the air and blowing the air to the mother board. M200 and M200 Plus uses the same mother board as far as I see, but M200 Plus has additional LCD board on it. This is 24V system, so having more heat source than original M200. This is why I am putting the wooden plate and see how it goes.

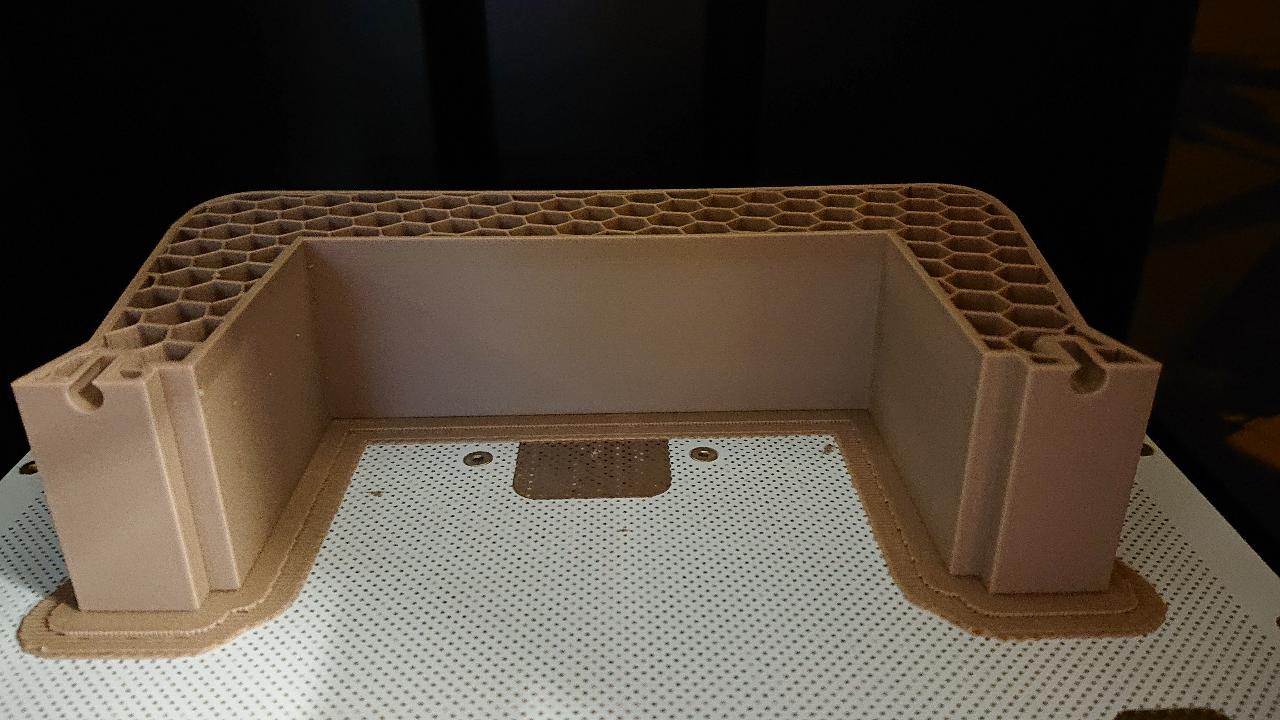

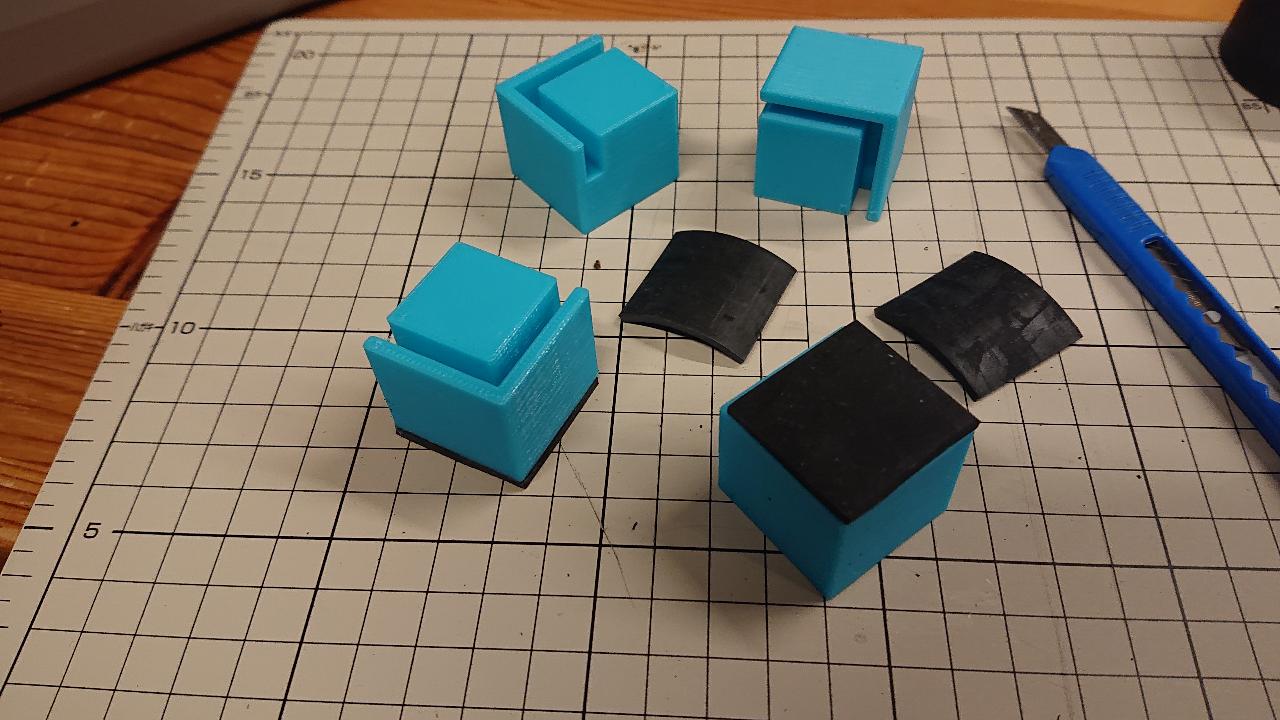

Now I am making the Corner Blocks for M200 Plus to raise this machine upward 15mm !! instead of the current thin corner bushings.

Prusa Helps Zortrax !!! … hahaha

Let’s see !!!