Hello,

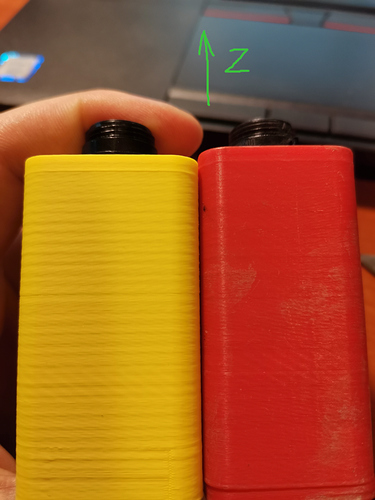

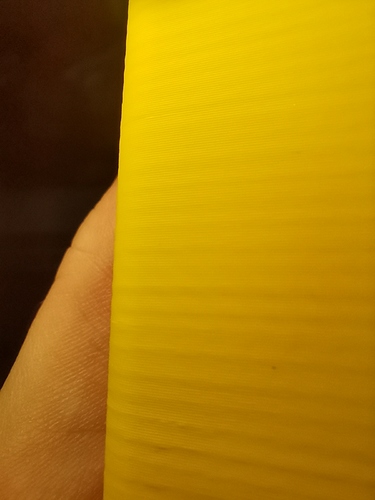

My M200 recently developed printing artifacts that look like ringing but in Z direction.

I took couple of photos - both parts are printed form the SAME file (same zcode), red is older (~1.5 years). Material is the same (Z-ABS) just in different color.

Yellow part has horizontal bands that do not show up on the red part printed earlier. This does not look like belt tensioning problem since bands are in Z direction, I checked them anyways but it does not change anything.

Printer has ~3k hours on clock now and some part clearly is worn out or loosened, but which one should I check first?

Hello,

Please check the Z axis screws - they should be a bit loose, not fully tightened.

Does the platform move smoothy, or do you hear any unusual noises? Because Z-Axis Coupler may need tightening.

Best regards,

Karolina

Hello,

I touched these screws first time today since I got this printer and they are a bit loose (I left them alone, without tightening).

I checked upper Z coupler screw, ant then disassembled bottom plate and checked lower Z coupler screw - they are tight. Z coupler does not slip on motor shaft nor on the ball screw.

Platform moves up and down smoothly without any unusual noises and without play.

After disconnecting printer I can gently push platform up and down without too much resistance - it moves smoothly without any variations in force required to push it.

Since I already started dismantling the printer I cleaned and greased all the rods - they were moving smoothly but I noticed a bit higher friction towards the end of travel (on both X and Y, none on Z).

And continuity-checked extruder cable with multimeter - it seems to be fine.

I will print few test pieces tomorrow and report.

What is next in queue?

I suspect heater (again) - I already had to replace it twice (each time after ~1k hours), but it never failed completely cold, just started misbehaving - underextrusion, skipping steps in the extruder, nozzle clogs.

Maybe failing heater can produce banding too?

OK,

I printed some tests:

Blue is an old part (~2years) in Z-ABS

Yellow and red are new and have the same diameter as blue, just less height to print faster.

Red is Z-ABS and yellow is F3D ABS-FX

Yellow part has crappy surface finish compared to others but no banding (I probably need to mess with printing parameters some more)

Problem seems to have disappeared for now, but I have no idea what caused it in the first place:

Some dirt on guide rods?

Wonky connection to extruder cable that I inadvertently fixed when checking continuity?

Failing cable that now connects better because I shifted its position slightly?

Anyways,

Thank You for your time, my printer is good - at least for now