Hello world ![]()

I have just finished my first bottle of Resin Basic Pigment Free. It is very good looking transparent material but less precise than PRO Black…

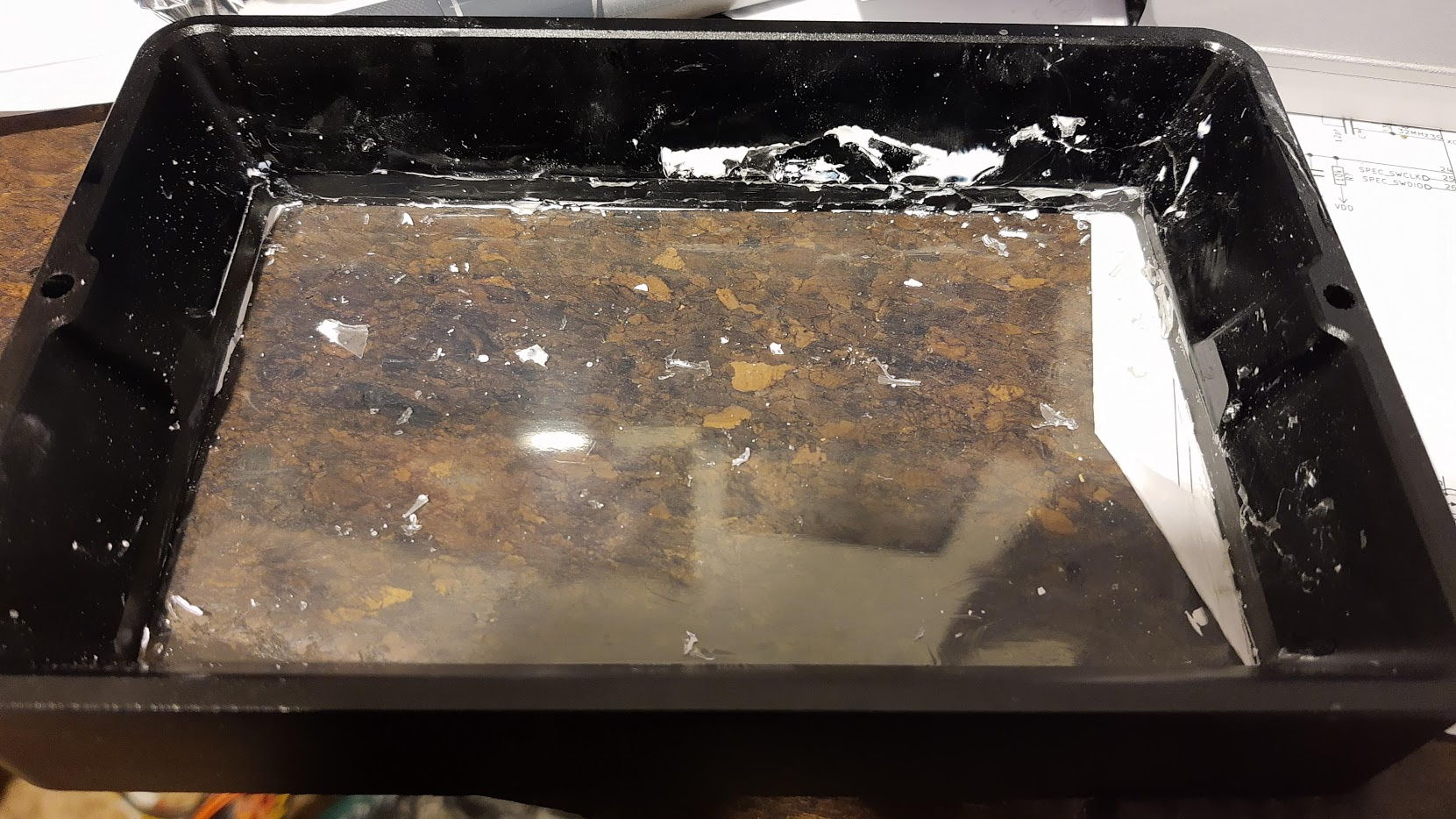

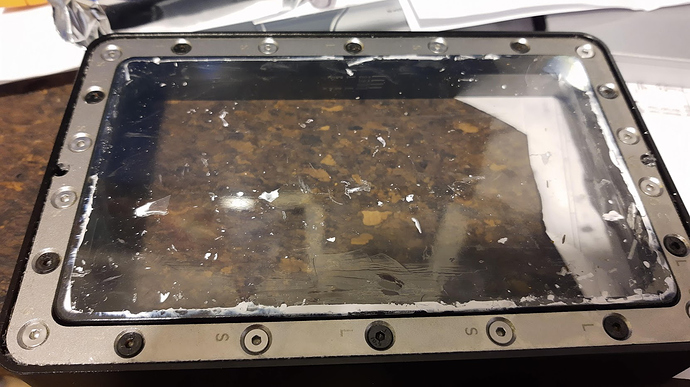

I have printed around 10 parts out of that bottle, one after another, it took several days (each one of them took around 15…30h)… but the problem is the resin gets stiff really fast. First printouts were very nice. Following printouts lost its precision because the resin was turning from liquid more and more into a honey like substance that was hard to remove from the printout. The last print was very sticky and the resin tank got glued and top of it turned into milk skin that very quickly turned into a solid plastic.

After I got intoxicated several times with IPA and said myself I will not use it anymore with Inkspire, I considered it the only way to clean up the resin tank… but it did not help. The plastic on the film could be crushed and removed but I don’t know how to remove the plastic resin cover from the tank walls and IPA does not melt it. I am afraid that using Acetone or mechanical scrubbing will damage the tank.

Some observations on Resin Basic Pigment Free:

- it is extremely sensitive on temperature.

- it vaporized extremely fast.

- it turns quickly into skin then solid plastic.

- the whole bottle does not seem to live long enough for one after another print for several days.

- it sticks to the resin tank and the film.

- brand new film replacement is sure after Basic Pigment Free printouts one after another whole bottle.

Questions:

- what can I use to safely dissolve Basic Pigment Free resin that turned into a solid plastic on my resin tank?

- did you observe such problems with Basic Pigment Free resin?

I am using brand new resin original delivered from your online shop. The tank was perfectly clean. The film was brand new. All printouts were made with plexiglass cover. I am using Inskpire in my room on the desk right next to me.

This is the first time I have encountered such situation and I am using Inkspire for over a year with different materials (Basic White, Flexible, Pro Black).

The only thing I can see is the higher temperatures outside. But this is located in my working room.

Any hints welcome ![]()

I have two more bottles to play

I have two more bottles to play  It would be good to know how to avoid such situations in future… the only thing that comes to my mind is either high ambient temperature or print chamber ventilation that would both decrease the inside temperature and gas condensation…?

It would be good to know how to avoid such situations in future… the only thing that comes to my mind is either high ambient temperature or print chamber ventilation that would both decrease the inside temperature and gas condensation…?