Hello,

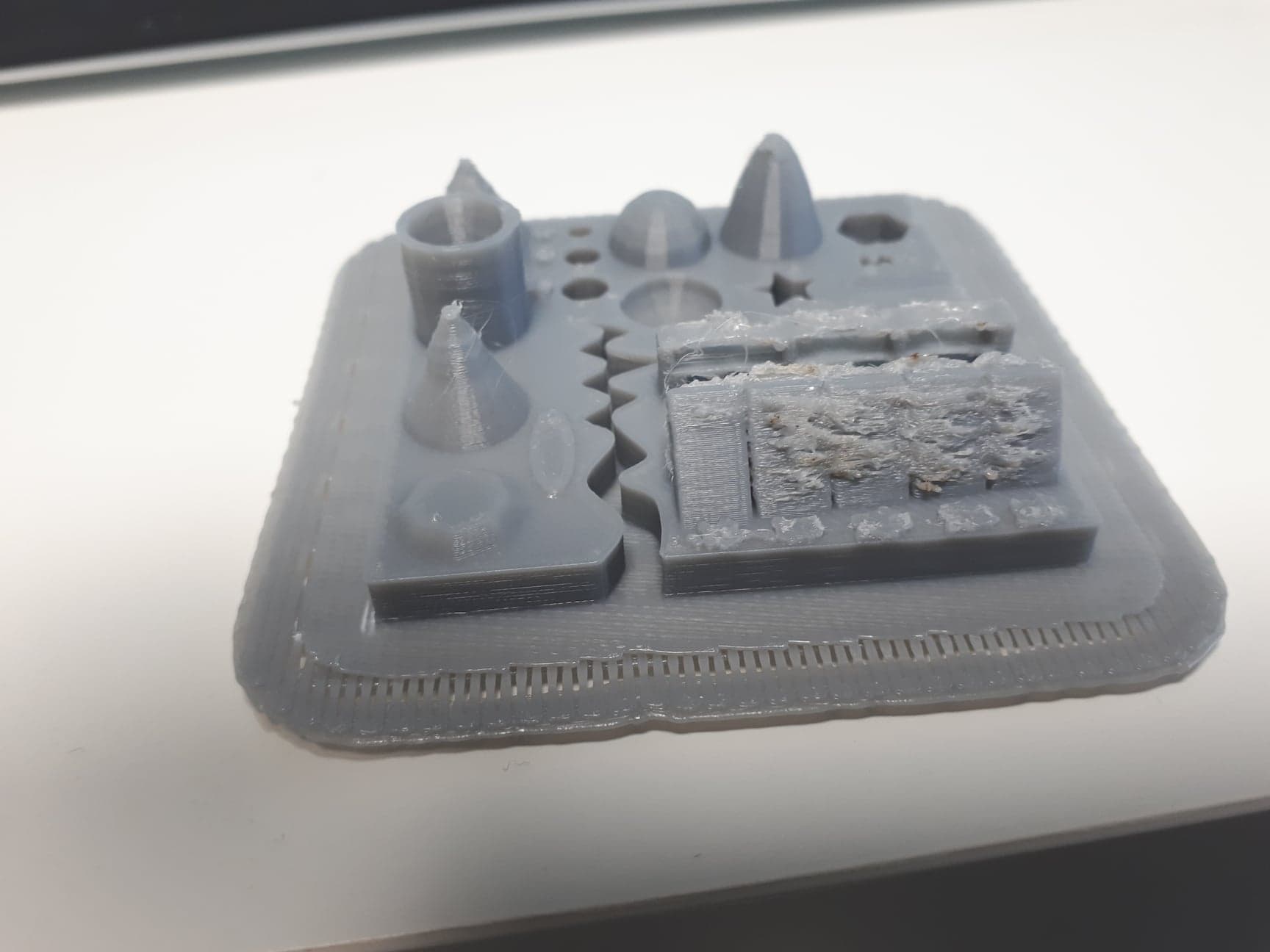

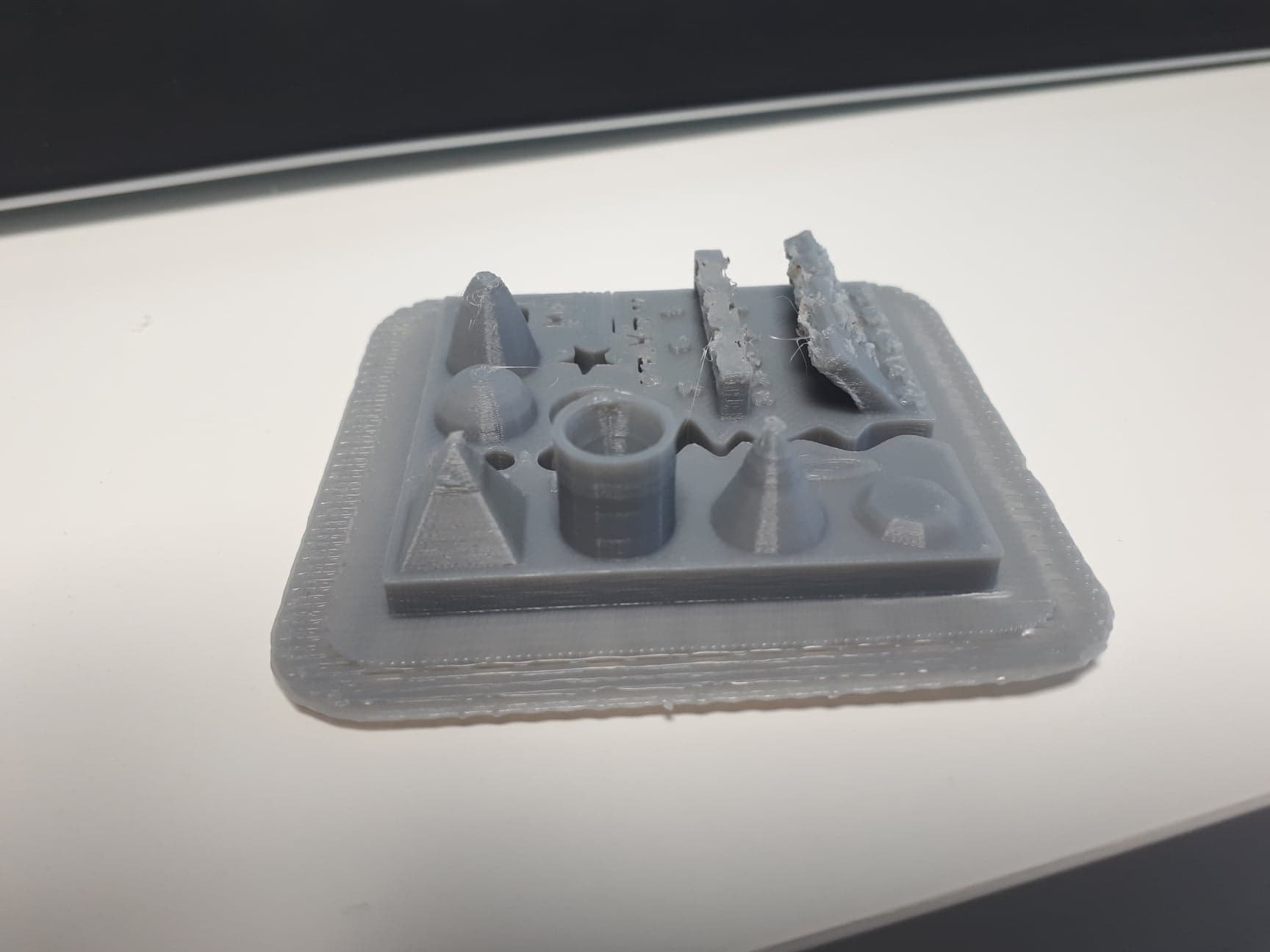

Well dont you think it should come out a lot better than that? I mean looking at what the other people made with 300$ printers Its kind of worry some: https://www.thingiverse.com/thing:704409/makes#makes

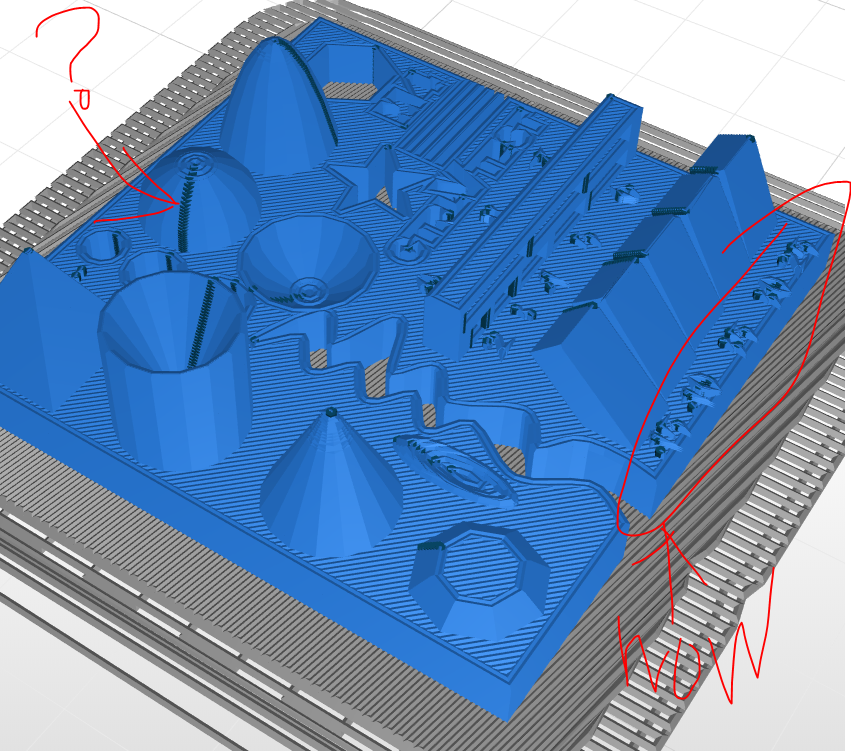

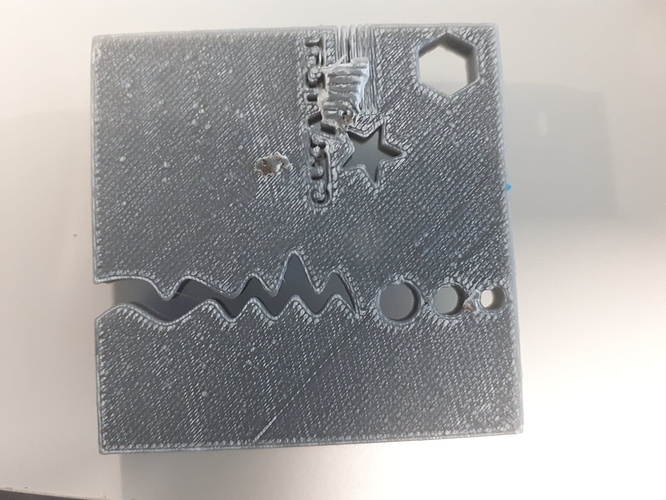

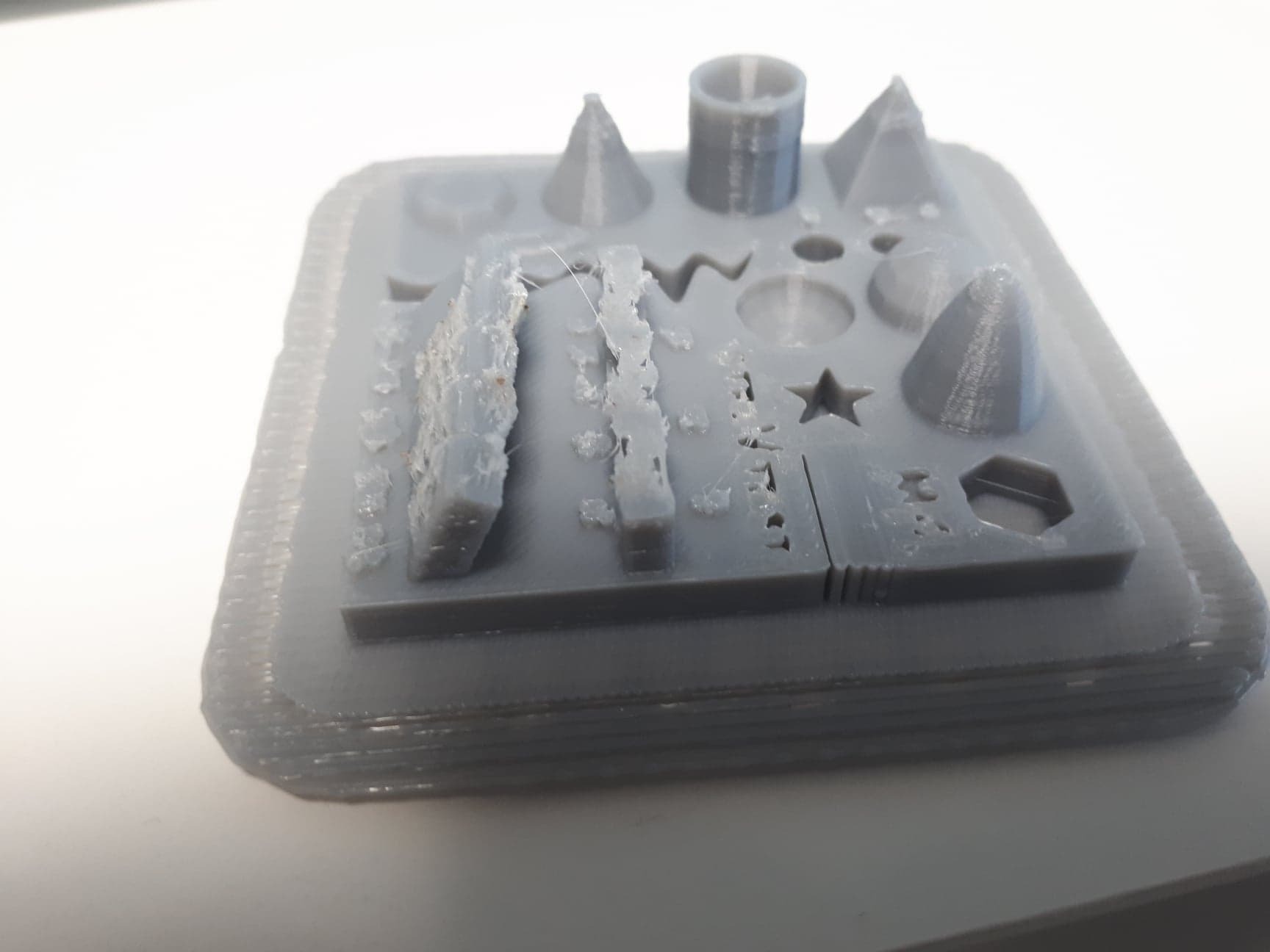

Anyways, about the other prints, other than the lack of small details as stated above I have 2 main problems.

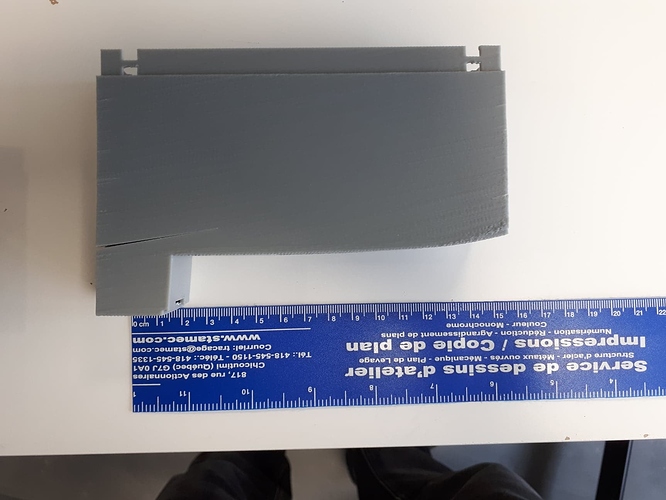

Warping/bended prints

Layers cracking/not adhering

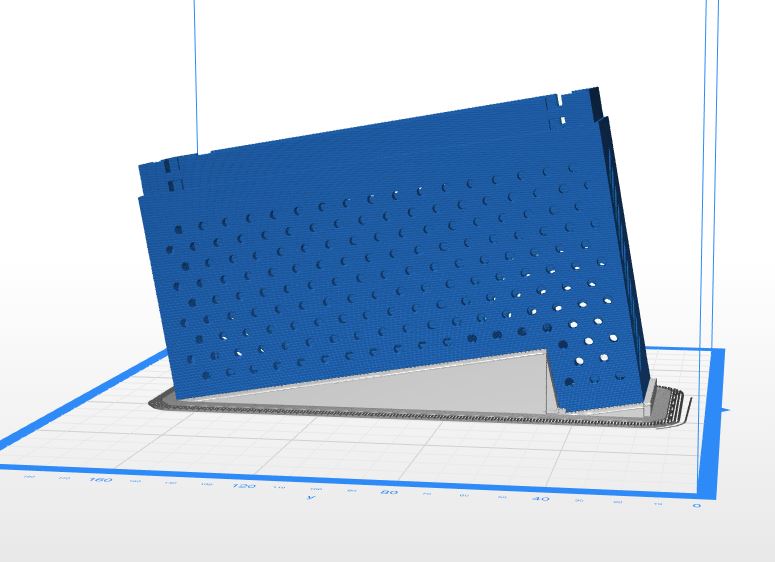

Every time I try to print an object at an angle I get terrible deformation. For instance lets picture a 10cm long U shaped object, well if I print it flat, its not too bad, if I angle it 35 degrees on the side, its bent.

Now, from what you can see on the picture my layers wont adhere either.

I tried ;

NYLON (external)

ABS (external) both normal and TITANX

Z-PCABS

Z-PETG

Z-ULTRA

None have worked and I can’t get an acceptable result.

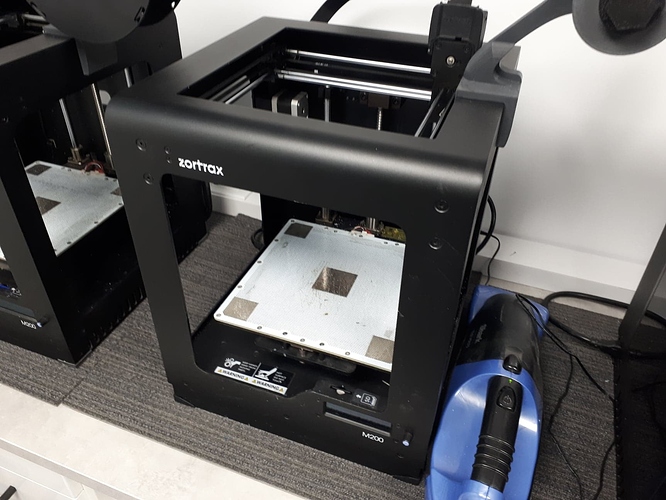

My printer setup is in a room with stable temperature, I tried both the enclosed and the open M200, many différents settings. Can’t get it to work.

Application version: 2.16.1.0

Estimated print time: 11h 0m

Material usage: 32.85m (78g)

Printer: Zortrax M200

Profile: Last settings

Support type: Editable

Material: Z-ULTRAT

Nozzle diameter: 0.4 mm

Layer: 0.19 mm

Quality: High

Infill: 30%

Fan speed: Auto

Seam: Normal

Outer contours: 0.00

Holes: 0.00

Surface layers Top: 6

Surface layers Bottom: 6

Support Lite: Yes

Smart bridges: Yes

Support offset: No

First layer Density: 100%

First layer Print speed: 100%

First layer Flow ratio: 100%

First layer gap: 0.31 mm

Raft Enabled: Yes

Raft layers: 6

Platform-raft gap: 0.25 mm

Raft Density: 100%

Raft Print speed: 100%

Raft Flow ratio: 100%

Support Density: 4.00 mm

Gap XY: 0.53

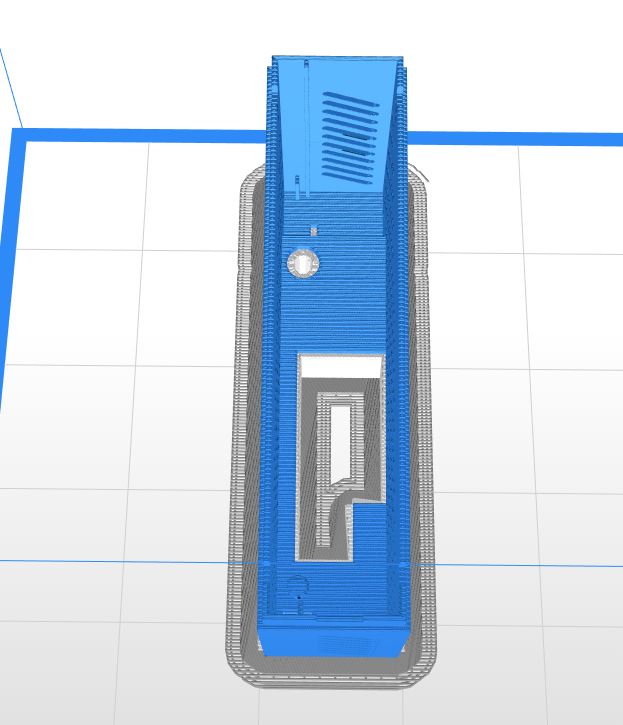

Application version: 2.16.1.0

Estimated print time: 15h 43m

Material usage: 39.59m (94g)

Printer: Zortrax M200

Profile: Last settings

Support type: Editable

Material: Z-ULTRAT

Nozzle diameter: 0.4 mm

Layer: 0.14 mm

Quality: High

Infill: 30%

Fan speed: Auto

Seam: Normal

Outer contours: 0.00

Holes: 0.00

Surface layers Top: 8

Surface layers Bottom: 6

Support Lite: Yes

Smart bridges: Yes

Support offset: No

First layer Density: 100%

First layer Print speed: 100%

First layer Flow ratio: 100%

First layer gap: 0.31 mm

Raft Enabled: Yes

Raft layers: 6

Platform-raft gap: 0.20 mm

Raft Density: 100%

Raft Print speed: 100%

Raft Flow ratio: 100%

Support Density: 4.00 mm

Gap XY: 0.53

Application version: 2.15.2.0

Estimated print time: 12h 35m

Material usage: 39.51m (94g)

Printer: Zortrax M200

Profile: Last settings

Support type: Editable

Material: Z-ABS

Nozzle diameter: 0.4 mm

Layer: 0.19 mm

Quality: High

Infill: 30%

Fan speed: Auto

Seam: Normal

Outer contours: 0.00

Holes: 0.00

Surface layers Top: 6

Surface layers Bottom: 6

Support Lite: Yes

Smart bridges: Yes

Support offset: No

First layer Density: 100%

First layer Print speed: 100%

First layer Flow ratio: 100%

First layer gap: 0.31 mm

Raft Enabled: Yes

Raft layers: 6

Platform-raft gap: 0.31 mm

Raft Density: 100%

Raft Print speed: 100%

Raft Flow ratio: 100%

Support Density: 4.00 mm

Gap XY: 0.31

Application version: 2.16.1.0

Estimated print time: 10h 31m

Material usage: 33.44m (80g)

Printer: Zortrax M200

Profile: TitanX

Support type: Editable

Material: ABS-based filament

Nozzle diameter: 0.4 mm

Layer: 0.19 mm

Quality: Default

Infill: 30%

Fan speed: Auto

Seam: Normal

Outer contours: 0.00

Holes: 0.00

Surface layers Top: 6

Surface layers Bottom: 6

Support Lite: Yes

Smart bridges: Yes

Support offset: No

First layer Density: 100%

First layer Print speed: 100%

First layer Flow ratio: 100%

First layer gap: 0.25 mm

Raft Enabled: Yes

Raft layers: 6

Platform-raft gap: 0.29 mm

Raft Density: 100%

Raft Print speed: 100%

Raft Flow ratio: 100%

Print speed: +0%

Extruder flow ratio: +0%

Top layer infill (%): 100

Bottom layer infill (%): 100

Extrusion temp.: 275

Platform temp.: 80

Retraction speed: 36

Retraction distance: 0.8

Support Density: 4.00 mm

Gap XY: 0.53

Application version: 2.15.1.0

Estimated print time: 12h 17m

Material usage: 33.48m (97g)

Printer: Zortrax M200

Profile: Last settings

Support type: Automatic

Support: 20°

Material: Z-PCABS

Nozzle diameter: 0.4 mm

Layer: 0.19 mm

Quality: High

Infill: 30%

Fan speed: Auto

Seam: Normal

Outer contours: 0.00

Holes: 0.10

Surface layers Top: 7

Surface layers Bottom: 5

Support Lite: Yes

Smart bridges: Yes

Support offset: No

First layer Density: 100%

First layer Print speed: 100%

First layer Flow ratio: 100%

First layer gap: 0.25 mm

Raft Enabled: Yes

Raft layers: 7

Platform-raft gap: 0.21 mm

Raft Density: 100%

Raft Print speed: 100%

Raft Flow ratio: 100%

Support Density: 2.50 mm

Gap XY: 0.28

Application version: 2.15.2.0

Estimated print time: 13h 33m

Material usage: 34.61m (105g)

Printer: Zortrax M200

Profile: Last settings

Support type: Editable

Material: Z-PETG

Nozzle diameter: 0.4 mm

Layer: 0.19 mm

Quality: High

Infill: 30%

Fan speed: Auto

Seam: Normal

Outer contours: 0.00

Holes: 0.00

Surface layers Top: 6

Surface layers Bottom: 6

Support Lite: Yes

Smart bridges: Yes

Support offset: No

First layer Density: 100%

First layer Print speed: 100%

First layer Flow ratio: 100%

First layer gap: 0.50 mm

Raft Enabled: Yes

Raft layers: 6

Platform-raft gap: 0.50 mm

Raft Density: 100%

Raft Print speed: 100%

Raft Flow ratio: 100%

Support Density: 4.00 mm

Gap XY: 0.43

I can’t share the files for this one unfortunatly.

Thank for the help.

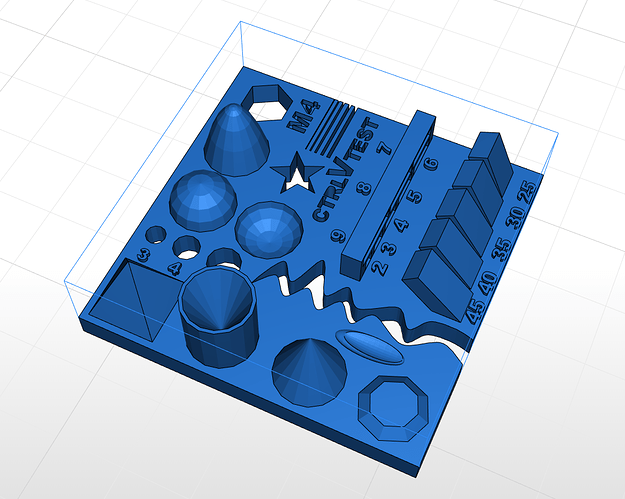

![]() ctrlV_3D_test.stl (329.5 KB)

ctrlV_3D_test.stl (329.5 KB)