Hi Guys,

Desperate for help here.

Got my Inventure few months ago, installed the cartridges it came with (PETG and support premium). After two weeks of moderate operation the extruder lower fan died. It took me a month to get a replacement during which the printer stood unused.

Yesterday I have replaced the fan and I assembled the printer back carefully. After re-loading the materials printer did work - for a total of 5 hours.

I came back to the room it stands in (to check on the process) and I saw that the support material literally sticking out from the side of the printer all jammed up and curled (like old tapes would do when you had a jam - only good example I can think of). Printer displayed a support material jam error.

I tried to unload the material several times to no avail. It would not come out of the feeder tube. I have taken out the extruder part and then I confirmed that the support was indeed jammed inside the extruder part and would not budge.

I have taken to disassemble the extruder assembly in hope of freeing the support material.

Here are the pictures of what i have found:

By the way Zortrax admins, 3 photos limit for new users is an excellent way of adding an insult to the injury. Well done.

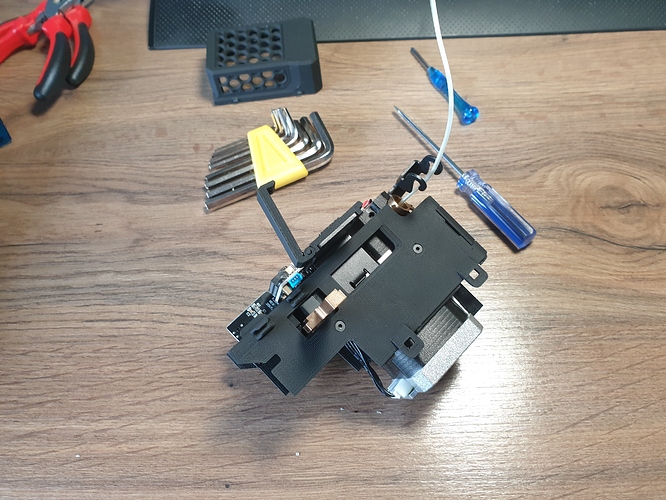

Before disassembly:

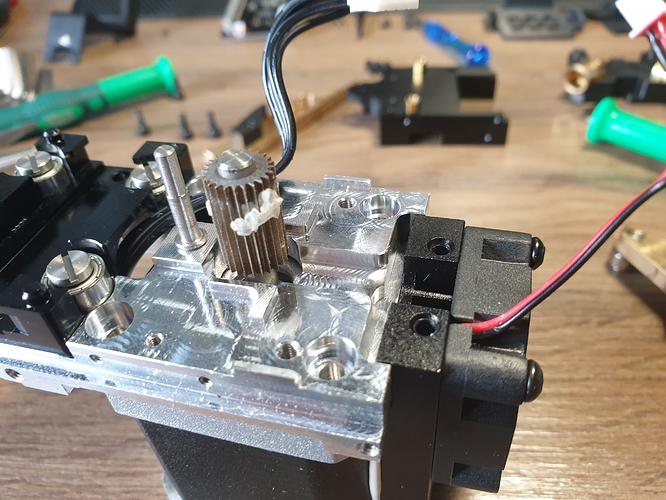

I have found out that the material was wrapped around the main motor gear:

Bits of the material were stuck to it:

Also you cant see it here, but this part was completely packed inside with this stuff, to the point that there was no way in the world any material would go through it.

I had to disassemble that small part and clean it inside.

After cleaning I have assembled everything back together carefully and meticulously.

I have re-assembled the printer, went through all the proper maintenance procedures (loading material, hot ends maintenance, alignments and so on). Both ends were extruding, i extruded quite a lot of the support material just to be sure. Everything seemed fine.

I started to print again. Printer started to print. I left the room for 15 minutes and came back to the similar problem. However printer was not showing any errors this time - it was just printing with invisible support material. Nothing was coming out and the printer continued as if nothing was wrong.

This time the material was not rolled and sticking outside.

When I unloaded it, it actually unloaded this time and the end of the spool came out - but it would not reload so I am assuming it has jammed inside again.

My questions are, is this a send it back and have a professional look at it issue? (I am so far behind with my project that I fear that doing it this way will cost me way too much time).

Can a support material deteriorate over a month of not use (it was in a cartridge)?

Can the hot end be the issue here? (nozzles were clean and the hot end part was free of blockages, i could slide a piece of filament through it with no issues what so ever)

Thanks for any help.

) then your support material is gone and there is nothing you can do about it. If it doesn’t make that sound when extruding then the issue will be somewhere else but I have no idea where.

) then your support material is gone and there is nothing you can do about it. If it doesn’t make that sound when extruding then the issue will be somewhere else but I have no idea where.

Really glad to hear this did the trick! Yes, storing the support material in an airtight box is a great idea. This should allow you to avoid similar issues in the future.

Really glad to hear this did the trick! Yes, storing the support material in an airtight box is a great idea. This should allow you to avoid similar issues in the future.